CMYK Laser Cut Woodblock Print with Diode Press

Home » Our Product Lines » Printmaking » Block Printing » Get Inspired | Block Printing » CMYK Laser Cut Woodblock Print with Diode Press

CMYK Laser Cut Woodblock Print with Diode Press

Have you ever thought about using a laser engraver to craft a four-block CMYK (Cyan, Magenta, Yellow, and Black) woodcut print? We will explore this process with Graham Stephens at Diode Press.

Image Preparation: Before proceeding with cutting the blocks, inking them up, and running them through the press, an image is needed. Graham created the artwork using ProCreate on his iPad, drawing it over several nights while reminiscing about childhood memories spent in the garage with his dad.

Photoshop Process: Next, he transferred the image from ProCreate to Photoshop, where he divided it into four halftone layers, each representing a color in the CMYK spectrum. Unlike traditional woodcuts that use spot colors, CMYK printing involves creating dots of each color to achieve various hues.

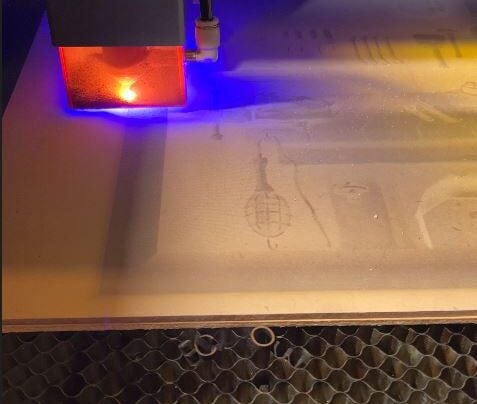

Lightburn Software: For controlling the laser, he utilized Lightburn software, importing PDFs of each layer and setting up the cutting parameters. Experimenting with speeds, power, and halftone resolutions was crucial to achieving the desired quality and detail.

Testing and Laser Cutting: Through testing different settings, Graham optimized the laser cutting process to ensure precise and detailed results. Each block required over two hours of laser time, emphasizing the need for continuous cutting to maintain alignment and avoid inconsistencies.

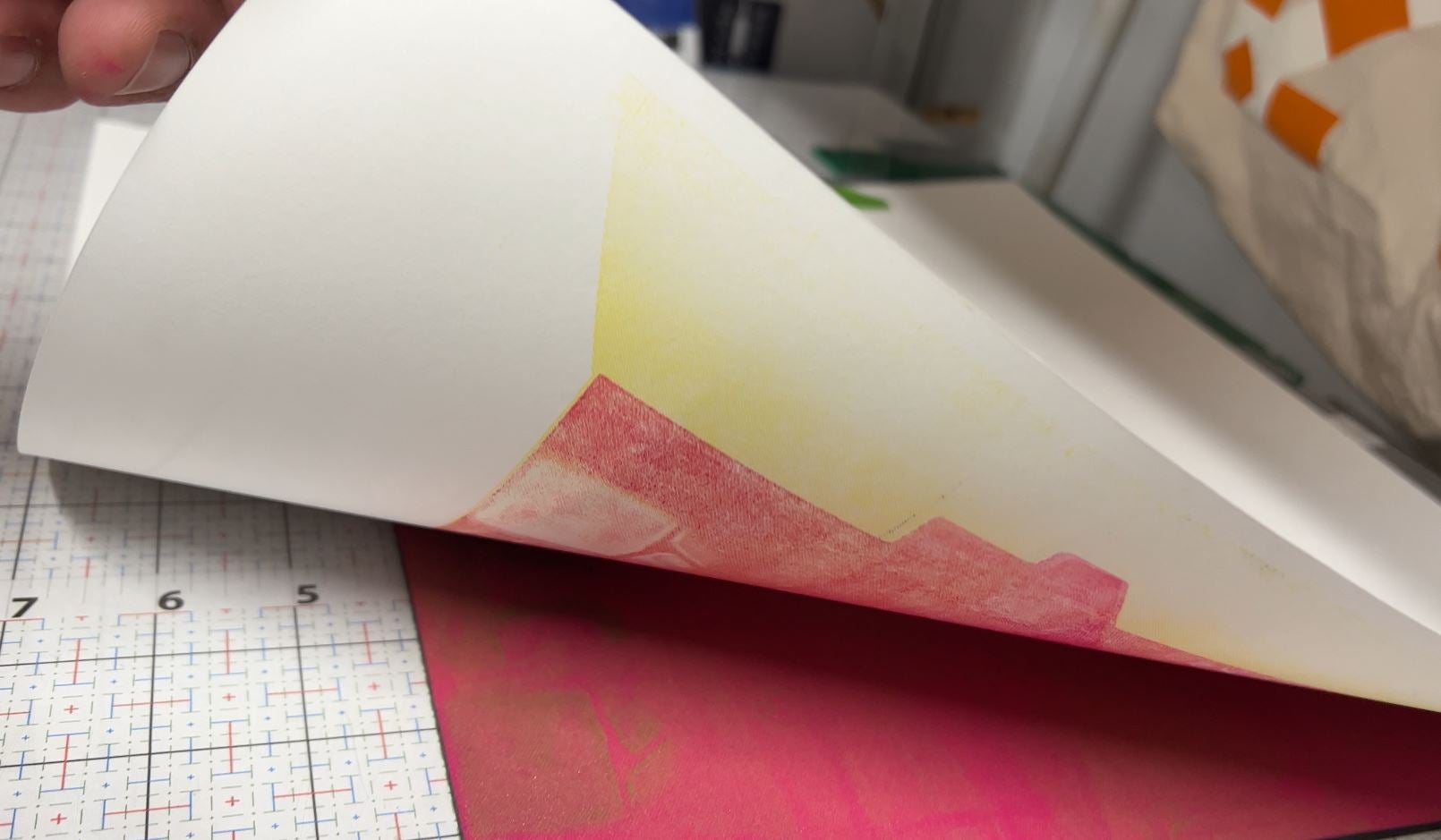

Paper Preparation: Along with the oil-based ink and Brayers provided to him from Speedball, he’s using Arnhem paper to print on. Each sheet was cut to size, and then he used Ternes-Burton registration pins to ensure proper alignment. This meticulous preparation ensured that each block lined up perfectly to create the intended colors and image.

Ink Selection and Printing: He used Speedball Oil-based ink, modifying colors as needed to match the CMYK process colors as best as he could. Printing began with the Yellow block, followed by Magenta, Cyan, and finally Black, gradually bringing the digital drawing to life on paper.

Final Print and Cleanup: Despite initial uncertainties due to the complexity of the project, the final image exceeded expectations, showcasing the intricate details and vibrant colors achieved through the CMYK woodcut process using a laser to cut the block. Cleanup after printing was simple with oil-based ink, requiring minimal effort and eco-friendly cleaning solutions.